VAV Box Control

VAV Box Control

I was working on a project for a client who owns many buildings. I put the new 90.1 2010 VAV box control sequence on the plans and was told that it was not in their control standards. In 90.1-2013, this control sequence is required for systems using DDC controls, which covers almost every building these days. My client’s problem is that it is clear that if we speed up the air flow in heating, we will use more heat and not save energy. That is true as far as it goes, but the box does not set the space heating load; it just responds to it. If the hot air flow increases, it increases to keep the space comfortable.

The problem really starts with Archimedes, but the guys over at ASHRAE 62 noticed that when hot air is both supplied and returned from the ceiling, it tended not to fall into the breathing zone. If the outside air they are so worried about does not get to the people, it is not useful. They suggest that 20% extra outside air might fix the problem. If you do not want to add 20% more outside air, you are limited to a maximum supply temperature of 15°F above the thermostat design set point for heating.

When 90.1 looked at the situation, we took a little different approach. First, let’s think about VAV box operation. I am not from Archimedes’ time, but I do remember when we first started using VAV boxes. We had zero or 10% minimum sets and the boxes were good space temperature controllers. Now we default to a 30% minimum set and the boxes need reheat to control temperature. We have added a new control sequence to address this problem.

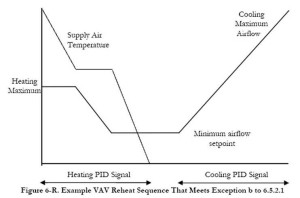

Let’s look at the new control diagram since we have it diagrammed here. As the space temperature drops, the box supply damper closes down to the minimum set. The supply air is normally around 55°F and so ,if the minimum set is 30%, it will continue to cool the space. The new sequence allows the minimum set to go down to 20% during the time the space needs neither heating or cooling. If we get lucky, there might be enough load in the space to hold the temperature steady at 20% airflow.

If we are not lucky, the hot water coil will open and we will be reheating the 55°F supply air. If we are reheating, how hot should we make the supply air? ASHRAE 62 says that the supply air from an overhead system cannot be more than 15°F above the room setpoint. It also says that the air has to be at traveling at 150FPM 4 foot above the floor. If the room set point is 68°F, the supply will be a maximum of 83°F. 90.1 agrees that it is true that the hot air tends to hug the ceiling and short cycle to the return grille. So, if we make it too hot or buoyant (Archimedes), it does not mix with room air and will not heat the people. The air device that manufacturers give throw adjustment charts for air streams that are different temperatures than the room air. Looking at these, we thought we could stand a 20°F difference. This raises the allowed supply temperature from 83°F to 88°F. At what temperature below body temperature will a person dressed for indoor winter conditions report a cold draft?

Here is what you have as a designer using the Standard 90.1 sequence we have had since 1999. You have selected a diffuser for the cooling airflow. Now it will be supplying 30% as much air as at design, plus you need to adjust the throw for buoyancy and still give the occupant a well mixed, comfortable temperature at chair level.

Remember that the heating load will be satisfied by CFM X delta-T X 1.085 (at sea level). This is the same delta-T as the one we are working with, so ASHRAE 62 delta-T is 15°. Normally ,when we size the heating equipment, we calculate the room heating load without taking credit for internal loads such as lighting, people, or plug loads. This probably gives us the right load for prewarming the room before it is occupied, but this load may be high for the occupied space. The cooling load is calculated based on a 20°F delta-T. This means that, if the load was the same, cooling would use less air. A recent study of an office building found that 0.3 CFM per square foot would satisfy the occupants. This would be a 100% OA system if you were meeting ASHRAE 62 requirements.

We decided that you might need to speed the air up to 50% of design airflow to meet the heating load and throw the air to the floor. Now we are heating the 55°F air to 88°F for a 33°F air temperature rise, without reset. As the fan speeds up to meet the heating load, we will use more energy. That is why we are using the 20% minimum set for this sequence. This transitional low airflow will balance out against the higher heating airflow and generally save more energy than the old sequence. We think that the warm air delivered at the higher airflow will be enough for you to heat the space. You just have to sell it to your customer. I am still working on this problem and will keep you updated.

Opinions expressed here are solely my own and do not express the views or opinions of ASHRAE or the 90.1 committee.